If you want to give your all, you need to know it all.

Complete solutions without interfaces and friction losses are only made possible through holistic, process-overreaching thought and action by qualified employees.

The benefit for our customers lies in the increase of productivity,

the reduction of costs and time as well as the complete concept being optimally adjusted to the customer.

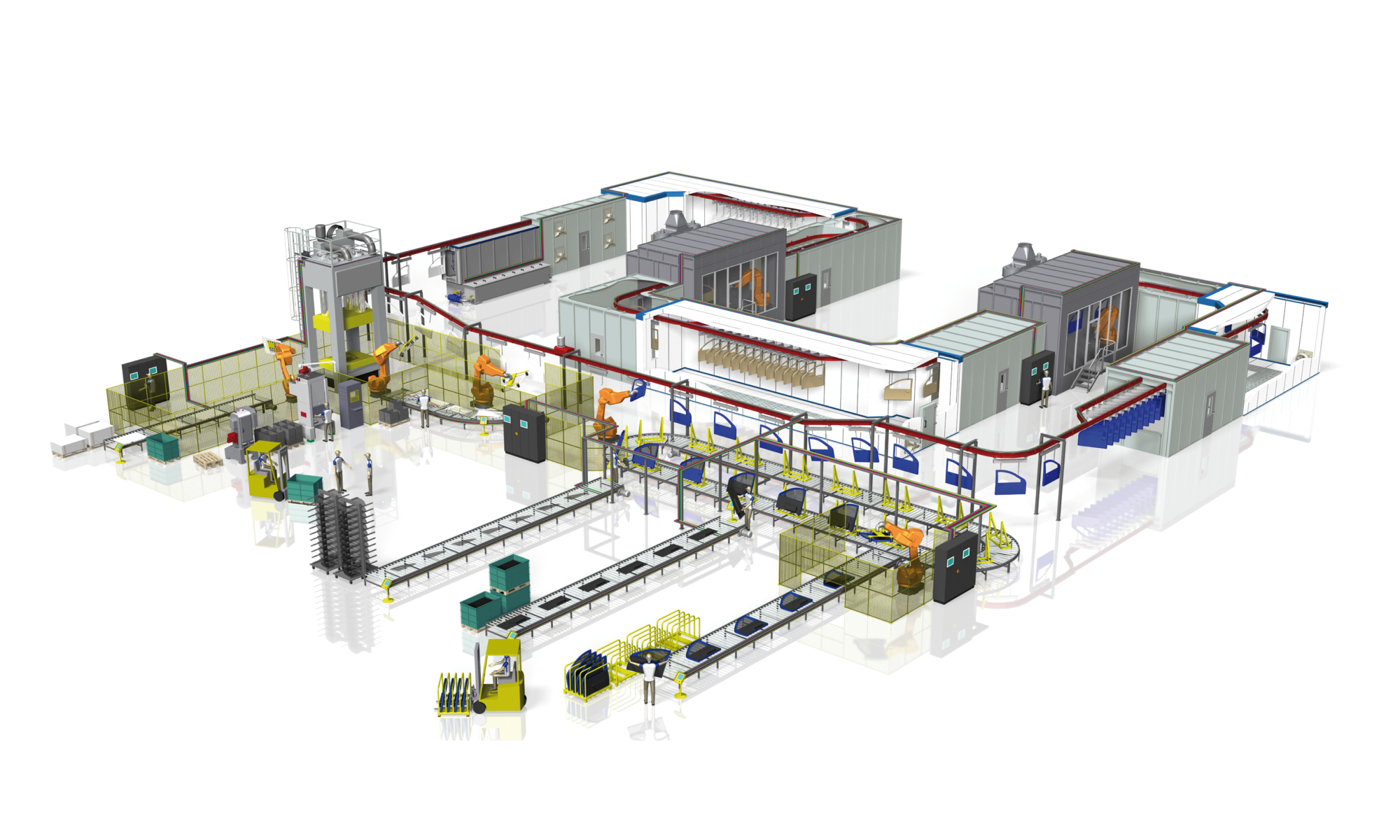

We accompany our customers through technological improvements as well as process optimization in manufacturing installations.

In addition to the full-range offer, we provide the possibility of taking charge of customer-specific application and development services:

- Counselling/Consulting

- Project analysis/Project layout

- Project development Hard- and Software

- Electrical and control construction

- Industrial assemblies

- Commissioning/Process introduction

- After-Sales-Service

Innovative and optimized processes.

Structured custom-tailored applications.

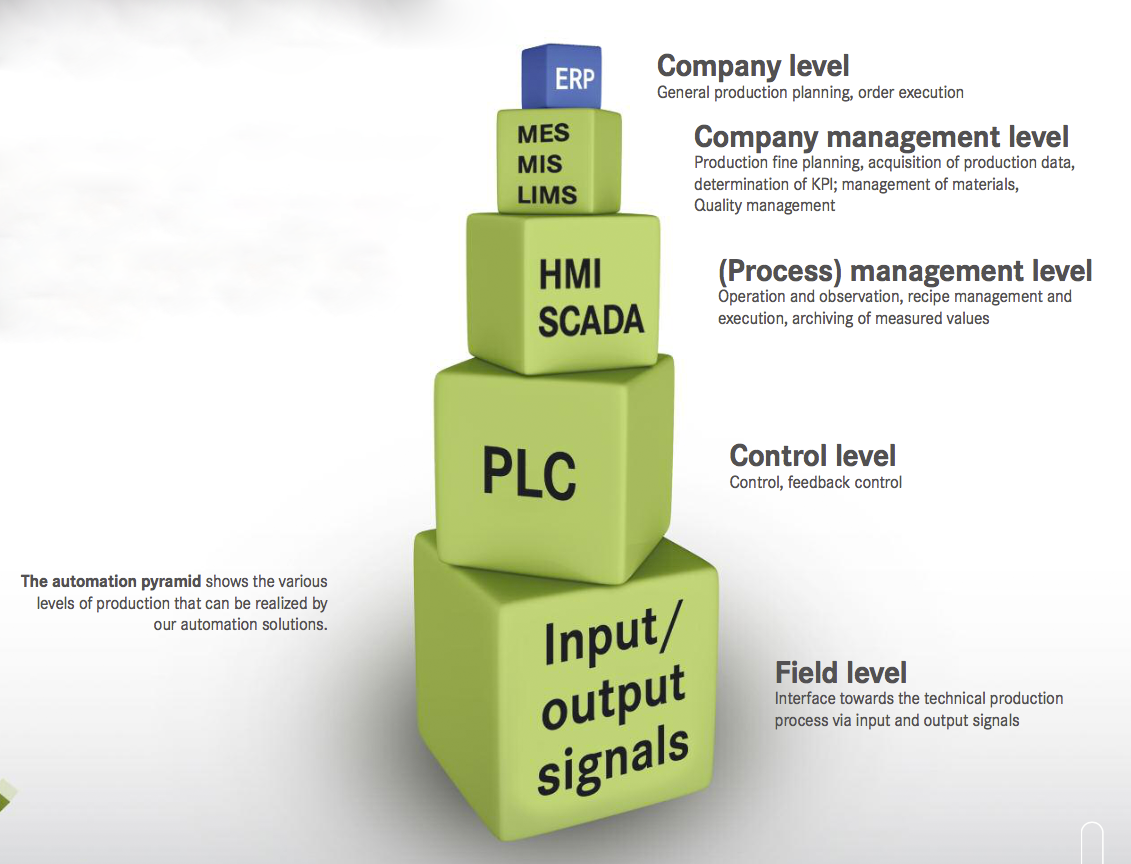

We accompany the project in the domain of automation engineering in a custom-tailored manner and without interfaces, using a branch-oriented ERP system.

We try to always provide the customer with the possibility of taking action during development thanks to the transparency of the project development phases.

A graphical control layout and corresponding HMI concepts that are prepared for and explained to the final customer and future operator of the machine ensure the highest degree of transparency and early acceptance of our ideas.

Project analysis

The industrial environment (Manufacturing/Process automation) requires a detailed analysis of the scope of the projects and targets. Only these information allow the corresponding selection of innovative technologies in the domain of hard- and software components and reaching of the project target.

The industrial environment (Manufacturing/Process automation) requires a detailed analysis of the scope of the projects and targets. Only these information allow the corresponding selection of innovative technologies in the domain of hard- and software components and reaching of the project target.

Circuit & controller construction

After the CAE planning, the project development data are transferred to the corresponding departments (Acquisitions, workshop, accounting).

After the CAE planning, the project development data are transferred to the corresponding departments (Acquisitions, workshop, accounting).

This forms the basis for the smooth execution of our electrical installation construction as perISO 9001:2015 in our own manufacturing facility.

Download Certificate ISO9001.2015

Hardware and software project development

The use of state of the art and high-performance CAE- (EPLAN) and PLC-software systems guarantee innovative and future- proof installations.

The use of state of the art and high-performance CAE- (EPLAN) and PLC-software systems guarantee innovative and future- proof installations.

The PLC project development is implemented based on customer requirements (BV/Factory stan- dards) in accordance with the selected automation system.

Industrial assemblies

Electrical engineering in the industrial environment must be performed in close collaboration between the customer and supplier. Discussions and clarification of details during the installation phases ensure a rational and technically high-quality electrical installation.

Electrical engineering in the industrial environment must be performed in close collaboration between the customer and supplier. Discussions and clarification of details during the installation phases ensure a rational and technically high-quality electrical installation.

Commissioning and process introduction

Transparency during commissioning and integration of the operator are pre- requisites for our relationship to the customer.

Transparency during commissioning and integration of the operator are pre- requisites for our relationship to the customer.

Further measures, such as instruction and “Training on the Job” complete our offer. The acceptance criteria are clarified with the customer beforehand so as to gua- rantee a smooth execution all the way through.

After sales and service

We are highly invested in constantly improving our service culture. This encompasses: Remote maintenance, maintenance contracts, preventive care, repairs and service missions.

We are highly invested in constantly improving our service culture. This encompasses: Remote maintenance, maintenance contracts, preventive care, repairs and service missions.

Retrofit / Revamping

Our years of experience make us the perfect partner when it comes to topics like retrofit and revamping. In the modernization or conversion of existing plants, our customers benefit from the experience we have gained and innovations that we have implemented over the last decades. We know the techniques of that time and are very close to the innovations of tomorrow.

The industrial environment (Manufacturing/Process automation) requires a detailed analysis of the scope of the projects and targets. Only these information allow the corresponding selection of innovative technologies in the domain of hard- and software components and reaching of the project target.

The industrial environment (Manufacturing/Process automation) requires a detailed analysis of the scope of the projects and targets. Only these information allow the corresponding selection of innovative technologies in the domain of hard- and software components and reaching of the project target. After the CAE planning, the project development data are transferred to the corresponding departments (Acquisitions, workshop, accounting).

After the CAE planning, the project development data are transferred to the corresponding departments (Acquisitions, workshop, accounting).

The expansion and extension of the customer and service potential for our business domains under consideration of the INNOVATION & TECHNOLOGY guiding principle are our primary targets for the future. The high quality and performance level is ensured through the constant expansion of system partnerships with manufacturers.

The expansion and extension of the customer and service potential for our business domains under consideration of the INNOVATION & TECHNOLOGY guiding principle are our primary targets for the future. The high quality and performance level is ensured through the constant expansion of system partnerships with manufacturers.